|

|

|

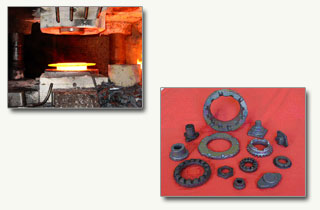

| PRESSING – MELTING – BAR CUTTING |

|

|

The Company processes about 18,000 tons material per year |

|

|

Material processed: |

|

| |

Steel – Cast iron – Aluminium – Sintered steel – Stainless steel |

|

|

Capacity: 0,2 to 16 kg pc. |

|

|

|

SPressing by presses with the following powers: |

|

| |

- 750 Tons |

|

| |

- 1000 Tons |

|

| |

- 1600 Tons |

|

| |

- 2500 Tons |

|

|

|

|

|

|

|

| HEAT TREATMENT |

|

The Company manages the heat treatment stages of the raw material through Suppliers Qualified and Certified according to UNI EN ISO 9001:2000 Standard, in compliance with the Customer’s technical specifications.

Treatments performed : |

|

|

Hardening and Tempering |

|

Annealing |

|

Normalizing |

| Heat treatments can also be performed in Controlled Atmosphere. |

|

|

|

|

|

|

| PROCESSING |

|

| Our core business is the high-precision machining on metal/aluminium/cast iron workpieces having a diameter ranging from 35 to a 350. Such activity is split up among three production shops: |

|

|

Workshop 1: machining on CNC-machines with automatic feeding (big-series production) |

|

Workshop 2: machining on one/two-spindle CNC-machines with manual feeding, CNC machining centres and multitasking machines (this sector is quickly evolving thanks to constant and targeted investments) |

|

Workshop 3: machining in specific-purpose workstations, transfer and accessory machining such as milling, drilling, honing, stamping, deburring (also with electrolytic burring machines). Ultrasound washing and packaging line according to the Customer’s technical specifications |

|

|

|

|

|

|

| SURFACE TREATMENT |

|

| The Company manages the surface treatment stages, through Suppliers Qualified and Certified according to UNI EN ISO 9001:2000 Standard, such as: |

|

|

Galvanising with passivations of different colours |

|

Phosphatising |

|

Nitriding / Nitrocarburizing |

|

Induction hardening |

|

Casehardening |

|

Carbonitriding |

|

Painting |

|

Gleitmo |

|

Precote/Loktite |

|

|

|

|

|

|

WASHING/PACKAGING

The cleaning, washing and packaging operations are carried out in accordance with the Customer’s technical specifications. For this purpose the Company has provided itself with a ultrasound washing line. |

|

|

|

|

|

STORING

The material finished, ready for sale, is stored within a warehouse so structured as to guarantee the stock rotation according to the FIFO standard. |

|

|

|

|

|

CHECKS

All checks are performed in compliance with the specifications received from, and agreed with, the Customer. For further details, visit the Quality area. |

| |

|